THERMAL TRANSFER LABELS

The Science and Application of Thermal Transfer Labels

In the world of labeling, durability and precision are paramount. Thermal transfer printing technology stands out as a premier choice for creating high-quality labels that can withstand challenging environments. United Paper Inc. is at the forefront of this technology, providing thermal transfer labels that cater to a myriad of industrial needs.business, or to request samples, contact us.

Understanding Thermal Transfer Printing

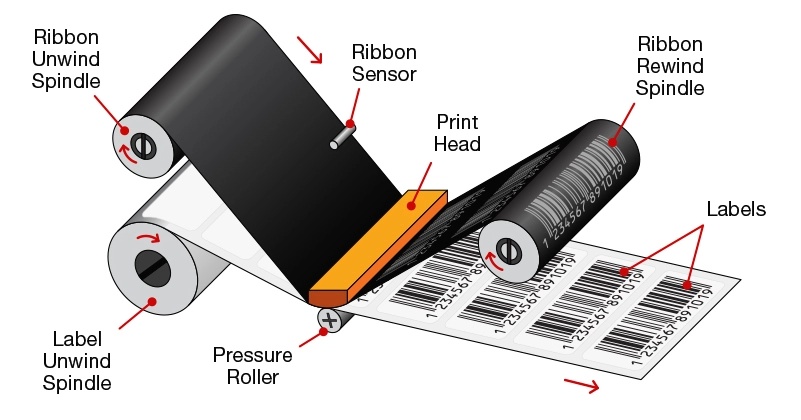

Thermal transfer printing involves the transfer of ink onto a label material through the application of heat. This process utilizes a thermal printhead that applies heat to a ribbon, which melts the ink onto the label to form the desired image. The key to the durability of thermal transfer labels lies in the choice of ribbon material. There are three primary types of ribbons used in this process:

- Wax Ribbons: Ideal for general labeling needs, wax ribbons are best suited for standard use on paper materials where minimal resistance to heat and chemicals is required.

- Resin Ribbons: Offering the highest durability, resin ribbons are resistant to high temperatures, chemicals, and abrasion, making them perfect for harsh industrial environments.

- Wax-Resin Blend Ribbons: These ribbons provide a balance between durability and cost, offering moderate resistance to environmental factors and suitable for a wide range of applications.

Applications of Thermal Transfer Labels

The adaptability of thermal transfer labels makes them a versatile solution for various industries. Here are some of the common applications:

– Manufacturing: Product identification, inventory management, and safety warnings are crucial in manufacturing. Thermal transfer labels ensure that critical information remains legible and intact throughout the product lifecycle.

– Logistics: In logistics, asset tracking and package labeling demand labels that can endure rough handling and varying climatic conditions. Thermal transfer labels excel in these areas, providing reliable performance.

– Healthcare: The healthcare sector requires labels for patient identification, specimen tracking, and medication labeling. The clarity and smudge-proof qualities of thermal transfer labels are essential for patient safety.

– Retail: Price tagging and shelf labeling in retail must be clear and durable. Thermal transfer labels resist fading and wear, ensuring that pricing and product information are always readable.

The Benefits of Choosing United Paper Inc.

United Paper Inc. offers a range of thermal transfer labels that are not only durable but also customizable to specific industry requirements. With a focus on quality and customer satisfaction, United Paper Inc. ensures that each label meets the highest standards of performance. Here are some benefits of partnering with United Paper Inc. for your labeling needs:

– Customization: Tailor your labels to the exact size, shape, and material needed for your specific application.

– Quality Assurance: Each label batch undergoes rigorous testing to ensure consistency and reliability.

– Expert Support: United Paper Inc.’s team of experts is available to guide you in selecting the right label solution for your business.

Conclusion

Thermal transfer labels from United Paper Inc. represent a fusion of science and practicality, providing a reliable solution for businesses that require labels to perform under pressure. Whether it’s resisting abrasion, chemicals, or temperature variations, these labels stand the test of time and environment, proving to be an invaluable asset across various industries.

For more information on how thermal transfer labels can benefit your business, or to request samples, contact us.